NX 8.5

NX 8.5 for Design

Improve efficiency and reduce design time with more powerful tools in NX 8.5. This latest NX release includes new and enhanced capabilities for feature modeling, sheet metal design, synchronous technology, freeform modeling, validation checking and drafting. Streamlined CAD workflows and an enhanced user experience improve productivity, minimize input, and reduce the effort required to accomplish design tasks.

NX 8.5 for Simulation

NX 8.5 introduces over 240 new simulation capabilities that help development teams engineer their products right the first time. New optimization tools combined with improvements in simulation modeling, as well as structural, thermal, flow, motion and multiphysics analyses, help you create innovative new products and speed simulation processes. Also learn what’s new in NX Nastran 8.5 for computational performance, accuracy, reliability and scalability.

NX 8.5 for Manufacturing

NX 8.5 boosts part manufacturing productivity in the machinery, turbomachinery, aerospace, medical, and mold and die industries. Save time programming and machining parts with new machining operations, more tool path control, and easier ways to automate programming. Close the quality loop by creating CMM inspection programs and analyzing results all directly within NX. From NC programming through to machining, save on tooling costs and use the right data with new tool library and CAM data management capabilities.

NX 8.5: Smarter Decisions, Better Products

NX 8.5 provides you with enhanced tools and technologies for product development. The latest release includes new and improved capabilities to increase design, simulation and manufacturing productivity.

Industrial Design & Styling

NX delivers a complete set of flexible shape creation, manipulation, and analysis tools and is an integrated part of a complete digital product development solution.

Package Design

NX software is an ideal tool for the challenges faced by package designers in the consumer packaged goods and food & beverage industries.

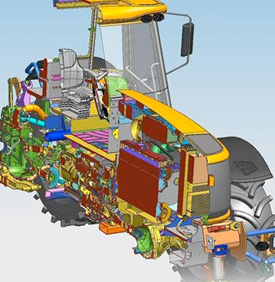

Mechanical Design

NX mechanical design tools deliver superior power, productivity, flexibility, and coordination for product development.

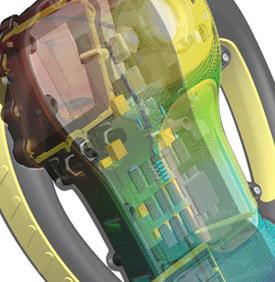

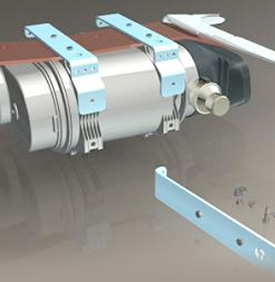

Electromechanical Systems Design

NX streamlines and accelerates electromechanical systems design with a solution that integrates mechanical, electrical, and electronic components.

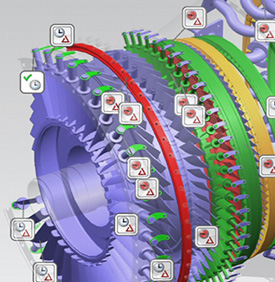

Visual Reporting & Analytics

NX delivers visual reporting and analytics with High Definition 3D (HD3D) technology to instantly gather PLM data and visualize its impact directly in the context of the 3D design.

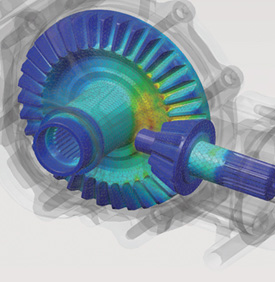

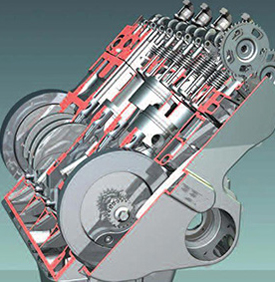

Mechanical Simulation

NX provides the industry’s broadest range of multi-discipline simulation solutions that leverage powerful capabilities in model preparation, solving, and post processing.

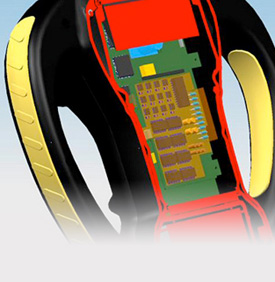

Electromechanical Simulation

NX includes simulation solutions for all of the primary failure modes for electromechanical products: temperature, vibration, and dust or humidity.

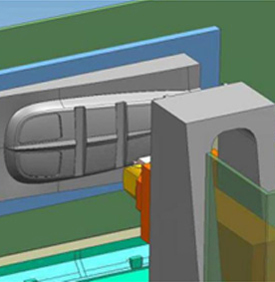

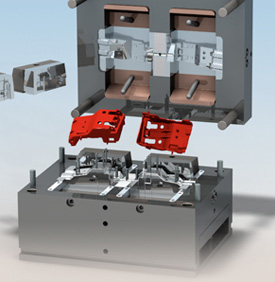

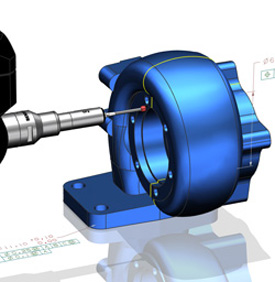

Tooling & Fixture Design

NX Tooling applications extend design productivity and efficiency into manufacturing, dynamically linking to product models for accurate tooling, molds, dies, and workholding fixtures.

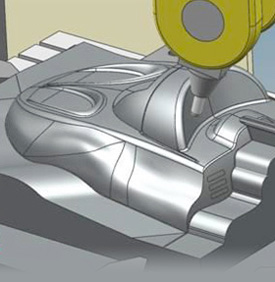

Machining

NX CAM delivers a complete solution for machine tool programming that maximizes throughput of the most advanced machine tools.

Engineering Process Management

NX engineering process management, powered by Teamcenter, provides a single source of product engineering and process knowledge, seamlessly integrated with CAD, CAM, and CAE.

Inspection Programming

NX CMM Inspection Programming enables you to automate programming to save time and improve accuracy.

Mechatronics Concept Designer

Mechatronics Concept Designer helps you design machines with greater speed and quality by providing a complete, end-to-end solution that enables easier collaboration between disciplines, reuse of existing knowledge, and better decision making through concept evaluation.

NX CAD

Design for the entire product lifecycle

Manufacturing companies are driven by increasing pressure to develop innovative products in shorter time frames, while maintaining high levels of quality. Even with mature, capable 3D CAD technology, many companies have failed to significantly improve their design processes, and the benefits of lower costs and shorter cycle times remain elusive.

Transformation of product development begins with the design process, which fuels the entire product lifecycle – from simulation and analysis through tooling design, manufacturing, assembly, service and support.

Next-generation design technology

NX from Siemens PLM Software delivers next-generation design tools and technologies that help companies transform product development. Leading-edge design tools work in the context of the total development effort, fully integrating design with the other disciplines that bring products to market in a unified, managed environment.

NX design tools are superior in power, versatility, flexibility and productivity. From innovative Synchronous Technology that unites parametric and history-free modeling to NX Active Mockup for multi-CAD assembly design, NX delivers breakthrough technology that set new standards for speed, performance, and ease of use.

Using Simulation to Make Faster, More Informed Decisions

Effective use of digital simulation can help project managers reduce many downstream costs and risks. Often referred to as computer-aided engineering, or CAE, simulation enables engineers to understand, predict, and improve product performance digitally. More design concepts can be explored, which in turn reduces direct costs associated with expensive physical prototypes and enables faster, more informed decisions. The result is better performing products and higher margins.

The keys to maximizing the value of simulation applications are to use them both as early as possible and then throughout the development process. To this end, Siemens PLM Software offers a comprehensive suite of Digital Lifecycle Simulation solutions designed to meet the needs of multiple users within any engineering enterprise.

NX Lifecycle Simulation delivers:

- Reusable processes and knowledge-driven CAE as a unified part of the NX Digital Product Development environment

- Scalability and consistencybased on high-performance CAE technology

- Industrial-strength productivity where CAE results are “current and in the design loop”

- Intelligent multi-CAD geometry idealization • capabilities for CAE which automatically update as the design changes

- Multi-discipline solutions through integrated multi-physics, multi-discipline FEA and CFD solvers, and design-integrated multi-body motion simulation

- Simulation process and data managementacross a global organization and virtual supply chain for managing CAE models, results, reports and CAE “best practice” processes

- Open support for industry standard CAD and CAE data exchange formats: Parasolid, IGES, STEP, STL, UNV, NBD, XML; standard 3rd party CAE software integrations including ANSYS, ABAQUS, LS-Dyna and MSC NASTRAN; and customizability for in-house solutions

- Global design collaboration using JT for lightweight visualization

Computer Aided Manufacturing (CAM)

Shorter product development cycles are the primary driving force in manufacturing. Continuous innovation and change in designs require more and faster development of numerical control programs, molds, tools and dies required to manufacture the product. Rapid technology change is increasing the complexity of the tools and processes used in manufacturing, and new methodologies are breaking down the walls between design and manufacturing operations.

As the world leader in computer-aided manufacturing, Siemens PLM software helps companies meet the challenge with leading edge solutions. More than point solutions for discrete production tasks, the NX suite of manufacturing software links design and manufacturing to improve productivity throughout tooling and fixture design and NC machining processes.

Advanced technology in NX tooling solutions automates and accelerates the development of molds, dies, and fixtures for higher quality, lower cost and faster turnaround. For machining, NX delivers the range and depth of CAM performance that maximizes returns on investments in advanced machine tools. Linked with proven data and process controls, NX helps companies manage information to improve productivity and collaboration in manufacturing operations.